PRODUCTS

PRODUCT

All categories

Number of views:

1022

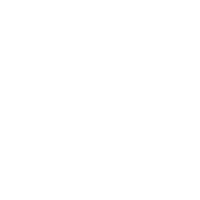

Square box

Retail price

0.0

Yuan

Market price

0.0

Yuan

Number of views:

1022

Product serial number

Quantity

-

+

Stock:

0

1

Product description

Square box is made according to JB/T3411.56-99 standard, material HT200, used for inspection and marking of parallelism and perpendicularity of parts. Square box is used to inspect or trace any angle line of precision workpiece, according to user requirements. Production of various specifications and contour boxes and rectangular tubes.

Cast iron square box is mainly used for the parallelism and verticality inspection of parts and supports workpieces when marking. It is generally a square or rectangular parallelepiped with the same side length. Various specifications and contour boxes and rectangular tubes can be made according to user requirements.

Uses: Square box is mainly used for inspection and scribing of parallelism and verticality of parts. The square box is a cavity cube of a specific six working faces made of cast iron, and one of the working faces has a V-shaped groove. Environmental conditions for square box testing: normal temperature, normal humidity.

Requirements: There should be no rust, scratches, cracks, dents and other defects affecting the metering performance of the working faces of the square box. The non-working surface should be sand-painted and chamfered. There should be signs on the inner wall of the square box, and marked with the size, grade number and manufacturer name.

Accuracy: Generally divided into three levels: level 1, level 2, and level 3.

Square box verification method: For a square box with a side length of 300 mm or less, a 1 mm gauge block is placed at each end of the square box to be inspected, and the knife edge is placed on the gauge block working surface, and then in each of the squares. At the checkpoint, the amount of the block is tested, and the difference between the size of the equivalent block group just inserted and the size of the block at both ends is the deviation between the two ends of the pair. This test shall also be carried out on several sections in the longitudinal, transverse and diagonal directions of the square face. When the error directions in the straight lines of the measured positions are the same, the large value is taken. When the error directions are inconsistent, the sum of the large positive difference and the large negative difference is taken as the flatness of the plane of the examined surface.

PRODUCT APPLICATION

Scan the QR code to read on your phone

Previous

T-slot square box

Next

Magnetic square box

PRODUCT

> 3D welding table

> Cast iron surface plate

> Cast iron angle plate

> Cast iron platform

> Cast iron square box

CONTACT US

Add:Botou Jiaohe Town Industrial Decelopent Zone

Tel:0317-8034818

Tel:0317-8176855 8177818

E-mail:hebei@yuan-peng.cn

Fax:0317-8031916

MESSAGE

Customer message

Description:

Copyright Hebei Yuanpeng Measuring Machine Tool Co.,Ltd. 冀ICP备19023384号 powered by www.300.cn